The Pietra Naturale Autentica (PNA – Authentically Natural Stone) Network – created to protect the competitiveness of authentically natural stone, its values and innumerable use possibilities and consisting of companies that work in the production process for stone slabs (extraction, cutting and surface finishing) – just concluded its first environmental analysis of the sector’s life cycle, aimed at quantifying the environmental impacts of a 1 square meter slab 2 cm thick.

Utilized for the purpose was the Life Cycle Assessment (LCA) methodology based on the ISO14040-44 standard and according to European Commission guidelines.

The LCA refers to the entire stone slab production chain, from the process of quarrying natural stone to sawing the blocks and subsequently giving the 2 cm slabs a surface finishing – including the energy and materials consumed and the scraps produced during all these stages.

Various companies in the PNA Network participated in the project: Antolini Luigi & C., Basaltina, Grassi Pietre, Margraf, Marmi e Graniti d’Italia, Marmi Ghirardi, Franchi Umberto Marmi, concentrating their analyses on multiple materials extracted and processed in Italy. Each project partner supplied data relating to its own quarry and production plant output.

The PNA’s LCA is sufficiently representative of the Italian stone sector because it considers different types of stone coming from different geographical areas in central and northern Italy.

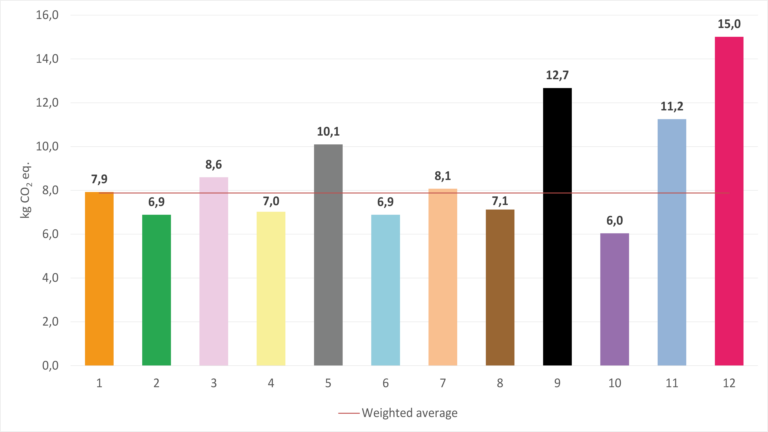

As shown in the graph in Figure, the impact on climate change proved to be between 6 kg CO2 equivalent per square meter and 15 kg CO2 equivalent per square meter, with an average value of 7.9 kg CO2 (a weighted average for the amounts produced by each company in the reference year).

This variability is physiological for this sector, in which processes (and relative energy and materials consumption) vary depending on the mechanical characteristics of the stone, as does yield, especially during the extraction stage.

Wishing to compare the environmental performance of stone stabs with a building material having a similar use destination (the so-called “functional unit”), analyses were made of the Environmental Product Declarations (EPD) for slabs and tiles in ceramic material with a 1.2 cm thickness (the most commonly used for floor and wall coverings).

With use destination being equal, the stone slab is environmentally more advantageous than a slab in ceramic material. In fact, a comparison with the available EPDs showed that the ceramic tile had impact varying from 15.5 to 29.9 kg of CO2 equivalent per square meter, while the average impact of a stone slab was of 7.9 kg of CO2 equivalent per square meter.

The LCA will be refined through a project that will begin in coming months in order to further increase representativeness, with the aim of sector environmental certification (an EPD for Italian Authentically Natural Stone), verified by a third party.

Source: www.naturalstoneisbetter.com